In the realm of medical laser instruments, the choice between optical fibers and copper cables is a crucial one. Medical laser instruments usually opt for optical fibers instead of copper cables, primarily due to the remarkable advantages that optical fibers offer in terms of transmission performance, safety, applicability, and more. Let’s take a closer look at these aspects through a detailed comparison.

- Transmission performance

Low loss:

Optical fiber can transmit laser signals, with extremely low transmission loss. Especially in the near-infrared band, the loss of optical fiber can be as low as 0.2 dB per kilometer or less, which makes the laser can be transmitted over long distances in the optical fiber and the signal strength attenuation is small.

The transmission of electrical signals over copper, due to the impact of resistance and other factors, the signal attenuation is faster, and users need to frequently use signal amplifiers to maintain signal strength.

High bandwidth: Optic fiber has an extremely wide bandwidth, ranging from 200MHz to 100Gbps. Optic fibers are capable of transmitting high-rate, large-capacity laser signals to meet the needs of medical laser instruments for high-resolution images and real-time transmission of large amounts of data. For example, in laser surgery, the need for real-time transmission of high-definition images of the surgical field of vision and laser control signals, optical fiber can easily handle this high data transmission task.

The bandwidth of copper cable is relatively narrow, ranging from 100MHz to 40Gbps.

No electromagnetic interference:

Optical fiber transmits optical signals, which are not affected by electromagnetic interference, and the signal transmission quality is stable and reliable. Medical environment there are a variety of complex electromagnetic equipment, such as magnetic resonance imaging (MRI) equipment, cardiac monitors, etc., the use of optical fiber can avoid the laser signal by these devices generated by electromagnetic interference, to ensure the precise control and stable operation of laser instruments.

When copper cable transmits electrical signals, it is easy to be interfered by external electromagnetic fields, resulting in signal distortion or miscoding. - Safety

Good insulation: Medical optic fibers are usually made of insulating materials such as silica, which have good insulation properties and do not produce the risk of electrical leakage, which can effectively protect the safety of patients and healthcare workers in medical applications. Especially in some laser therapy equipment that requires direct contact with the human body, insulation performance is crucial.

Copper cable is made of metal, which has the potential risk of electrical leakage and may cause safety accidents in humid or high-risk medical environments.

No electrical sparks:

Fiber optics do not generate electrical sparks during the transmission of optical signals, which is important for safety in some flammable and explosive medical locations, such as operating rooms and oxygen rooms.

In contrast, copper cables may generate electric sparks when power is turned on and off or when there is poor contact, posing a risk of fire or explosion.

- Applicability Good flexibility: Optical fiber has good flexibility and bendability, which can be flexibly wired and installed according to the internal structure and use requirements of medical equipment, and can adapt to a variety of complex spatial layouts. For example, in some minimally invasive surgical instruments, laser transmission channels need to be integrated into slender instruments, and the flexibility of optical fiber enables it to meet this special design requirement. Copper cables are relatively stiff and have a large bending radius, making them more difficult to wire in some medical devices with limited space.

- Corrosion resistance: Fiber optic material makes it has strong corrosion resistance, can be in the medical environment of a variety of chemicals and humidity conditions to maintain stable performance, long service life. Copper cable is susceptible to corrosion, especially in some medical places where chemicals such as disinfectants are often used, the outer jacket and internal wires of copper cable may be corroded, affecting its performance and service life.

- Cost: While it’s true that optical fibers are more expensive than copper cables initially, in the long run, they can actually prove to be the more cost – effective solution. This is because optical fibers require less maintenance, have a longer lifespan, and offer better performance, reducing the overall cost associated with system failures and replacements over time.

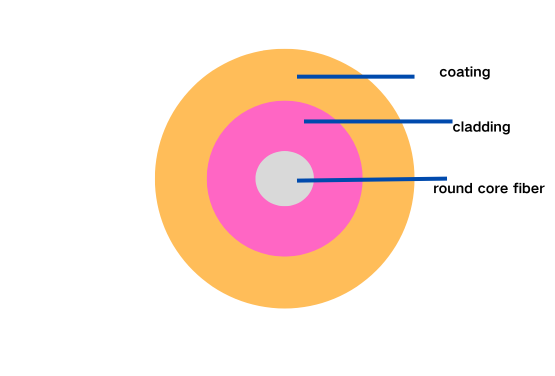

- Diameter:Diameters of common medical optical fibers are 200µm,275µm,550µm,400µm,600µm,1000µm (0.2mm-1mm)and etc. Overall, medical fiber is relatively small in size in microns, especially with a very fine core diameter, whereas copper cable is measured in millimeters and is overall much thicker than medical fiber.