Within the specialised field of fibre optic technology, END CAP CABLE beam expansion fibre plays a pivotal role in high – power laser applications and similar scenarios due to its unique structure and performance characteristics. Today, we delve into its applications and the key considerations for its use.

I. Applications: The ‘Guardian’ for High – Power Scenarios

(a) The ‘Safety Guardian’ for High – Power Laser Transmission

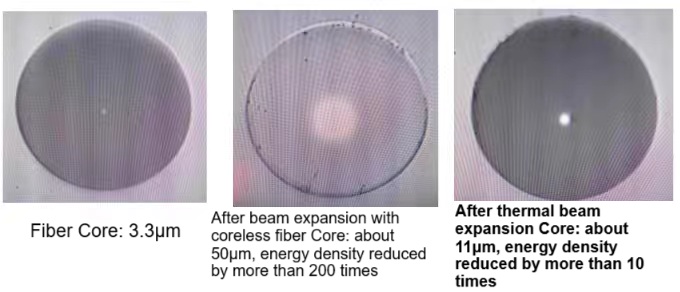

Consider this visual comparison of fibre end – face changes (illustrated): A standard Nufern 460HP fibre core measures merely 3.3μm. When high – power lasers pass through, energy becomes highly concentrated. Utilising beam – expansion technology, the core of a core – less fibre expands to approximately 50μm, reducing energy density by over 200 times. Following thermal beam expansion, the core width reaches approximately 11μm, reducing energy density by over 10 times. What does this signify?

Within fibre laser and amplifier systems, excessive energy concentration at the fibre end face during high – power laser transmission poses a significant risk of burnout. END CAP CABLE beam – expansion fibre effectively safeguards fibre end – faces by enlarging the core and dispersing energy. It is indispensable for applications such as high – power fibre lasers in industrial cutting and welding, or laser transmission in medical surgical equipment, enabling stable high – power laser operation without damaging the fibre.

(II) The “Stability Guardian” in Demanding Environments

Within industrial automation production lines, such as automotive welding workshops, where metal dust pervades and equipment undergoes constant vibration, traditional fibre connections frequently fail due to dust contamination or vibration – induced loosening. The end cap structure of END CAP CABLE beam – spreading fibres offers a degree of dust resistance, ensuring connection stability.

Within the fibre optic links of automotive LiDAR systems, even the intense vibrations of vehicle movement struggle to disrupt signal transmission. The end cap further shields the fibre end – face from rainwater and dust erosion. Remarkably, it maintains stable data transmission even in harsh environments like oil and gas fields or high – voltage substations, where electromagnetic interference is severe, thereby supporting equipment condition monitoring and data backhaul.

II. Usage Precautions: Key Details Not to Overlook

(I) Installation Phase: Precise Alignment is Paramount

During installation, meticulous fibre alignment is paramount. While expanded beams offer some tolerance, excessive deviation drastically reduces energy transmission efficiency and may damage fibres through localised overheating. Much like building blocks, each connection must be precisely aligned. Follow standard procedures using specialised tools to ensure end – face contact is secure and alignment is accurate.

(2) Environmental Adaptation: Prevent Environmental Limitations

While capable of withstanding complex environments, limitations exist. High temperatures, humidity, and corrosive conditions require prior assessment. For instance, in salt – fog – prone naval equipment, corrosion – resistant ferrule materials must be selected. In high – temperature industrial settings, monitor the temperature thresholds of both fibre and ferrules—exceeding these limits degrades material performance, compromising transmission or causing fibre damage.

(3) Maintenance: Regular inspections preserve performance

Periodically clean end – face surfaces, as dust or grease deposits increase attenuation. Use specialised fibre optic cleaning tools with gentle handling to avoid scratching. Also verify that fibre connections remain secure; prolonged vibration or frequent insertion/removal may cause misalignment, impairing beam expansion and energy transfer. Address any issues promptly through adjustment or reinforcement.

END CAP CABLE beam – expansion fibres are indispensable in high – power laser transmission applications. Understanding their purpose and adhering to usage precautions ensures sustained, stable performance. This safeguards associated equipment and systems, propelling fibre – optic technology forward in high – power domains.