Working Principle of DFB Butterfly Laser

The DFB (Distributed Feedback) butterfly laser operates on the principle that when current is injected into the active region, electrons and holes recombine to emit photons. These photons are reflected within the grating structure on the surface of the active layer, triggering stimulated emission. Through selective feedback and amplification by the Bragg grating, the laser produces output at a specific wavelength.

Performance Characteristics

The laser output boasts several key features:

- Stable wavelength and power for consistent operation.

- Single longitudinal mode output, ensuring high spectral purity.

- Excellent heat dissipation performance, critical for long-term reliability.

These characteristics make it an ideal high-precision, high-stability light source for applications in optical communication, fibre optic sensing, and laser ranging.

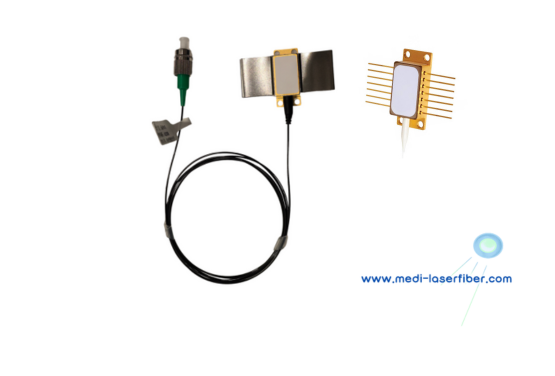

Butterfly-Shaped Tail Fiber Packaging via Laser Welding

How Does Laser Welding Achieve This Packaging?

Laser welding technology enables precise butterfly tail fiber packaging through a multi-step process:

- Preparation Stage: Align the laser and tail fiber to ensure precise positioning.

- Welding Process: Use a laser beam to heat the connection point, melting the metal to form a strong bond.

- Cooling and Solidification: Allow natural cooling or use a cooling system to ensure weld quality.

Impact on Laser Performance

- Compact Structure: Reduces the laser’s overall size, enabling high-density integration in limited spaces.

- Stability & Reliability: Laser welding ensures consistent power and wavelength stability, crucial for fibre optic communication and sensing.

- Heat Dissipation: An integrated semiconductor cooler maintains operating temperature via precise temperature control, enhancing performance consistency.

Safety Precautions for DFB Butterfly Lasers

To protect both personnel and the laser:

- Wear an ESD (electrostatic discharge) wristband. In experiments, plug one end into the driver’s grounding port and fasten the other end to the forearm, ensuring the metal plate contacts the skin.

Semiconductor Laser Display Driver Usage Steps

- Wear Anti-Static Gear: Use a wristband or gloves to prevent static damage.

- Secure the Laser:

- Open the clamp and place the laser in the butterfly fixture (avoid holding the pins).

- Align the fibre optic direction per the driver’s instructions and fasten the clamp.

- Connect Power: Check pin connections. An alarm (e.g., “Temperature sensing failure”) will display if there’s an issue.

- Set Parameters: Adjust laser current, TEC temperature, and upper current limit.

- Install and Power On:

- Attach the laser to the coupler, press the power button, and verify light emission.

- Allow 4–5 seconds for preheating; use a card at the output to check emission.

- Fine-Tune Settings: Use the driver’s side knob to adjust temperature and current via the touch screen interface.

Conclusion

DFB butterfly lasers combine precise wavelength control with robust packaging, making them essential for high-tech applications. Following proper usage and safety protocols ensures optimal performance and longevity.

Note: Always refer to manufacturer guidelines for specific operational details.