Optical fibers are the backbone of modern data transmission, but their performance can be easily compromised by one common issue: bending loss. Whether you’re working with fiber optics in a data center, telecom network, or home setup, understanding how bending affects fibers is critical to maintaining reliable signal transmission. Today, we’ll break down the key factors influencing fiber bending loss, why over-bending is problematic, and actionable ways to minimize this loss.

What Factors Affect the Magnitude of Fiber Bending Loss?

Fiber bending loss occurs when light energy dissipates or fails to reflect completely as the fiber is bent. Several key factors determine how severe this loss becomes:

1. Bending Radius

The most impactful factor is the bending radius. Simply put, the smaller the radius, the greater the loss. When the bending radius drops below the fiber’s specified minimum, significant standing wave loss and light leakage occur—this is when signal degradation becomes most noticeable.

2. Fiber Diameter

Thinner fibers are more prone to bending loss. In smaller-diameter fibers, light rays have a higher chance of contacting the core-cladding boundary during bending, leading to increased energy dissipation and greater signal loss.

3. Fiber Material

The material’s refractive index and dispersion characteristics play a role in bending loss. Different materials interact with light differently; some materials experience more distortion and energy loss when the fiber is bent, making them less ideal for applications where flexibility is required.

4. Fiber Structure

A fiber’s internal structure—such as the number of cladding layers and the combination of cladding materials—also influences loss levels. For example, fibers with multi-cladding designs may have varying resistance to bending loss depending on how the cladding materials are paired.

Why Should Fibers Not Be Excessively Bent?

Over-bending fibers isn’t just a minor oversight—it can cause lasting damage to both signal quality and the fiber itself. Here’s why it matters:

- Increased Signal Degradation: When a fiber is over-bent, light escapes the core and propagates through the cladding, resulting in significant light energy loss. This weakens the optical signal and reduces transmission efficiency.

- Unreliable Data Transmission: Over-bending impairs internal reflection in the fiber, making it harder for the receiving end to decode signals correctly. This leads to dropped data, slower speeds, and reduced overall reliability.

- Physical Fiber Damage: Beyond signal loss, excessive bending can physically harm the fiber—weakening its structure and shortening its lifespan. This can lead to costly replacements and network downtime.

How to Minimize Fiber Bending Loss

The good news is that bending loss is preventable with careful handling and proper practices. Here are four effective strategies:

1. Stick to the Recommended Bending Radius

Always follow the fiber’s specified minimum bending radius. Using a larger bending radius minimizes light energy dissipation, keeping loss to a minimum. Avoid tight bends, especially when routing fibers around corners or in confined spaces.

2. Use Low-Bending-Loss Fibers

For applications where flexibility is necessary (e.g., indoor cabling, portable devices), opt for low-bending-loss fibers. These fibers are engineered with specialized materials and structures to reduce light leakage during bending, making them ideal for bend-sensitive setups.

3. Implement Fiber Protection Measures

Use protective accessories to prevent over-bending. Fiber protection sleeves, break-resistant compensators, and cable management tools provide support and keep fibers from being bent beyond their limits—especially in high-traffic or high-flex areas.

4. Practice Careful Installation

During installation, avoid forcing fibers into tight bends or stretching them excessively. Use appropriate mounting fixtures to secure fibers and ensure their bending radius stays within the recommended range. Taking time to route fibers properly pays off in long-term performance.

5. Use Instruments to Detect Fiber Bending Radius

To ensure the fiber bending radius meets the standard, specialized detection instruments are essential. Common tools include fiber bending radius gauges (mechanical type) and optical time-domain reflectometers (OTDR, for indirect detection). Here’s how to use them correctly:

Fiber Bending Radius Gauge (Mechanical Type)

This is the most commonly used tool for on-site quick detection, suitable for routine inspection during installation and maintenance. Step 1: Select a gauge that matches the fiber type (e.g., single-mode or multi-mode) and its specified minimum bending radius. Step 2: Place the bent section of the fiber gently on the gauge’s curved groove, ensuring the fiber fits closely with the groove without forced pressing. Step 3: Observe if the fiber’s bending arc is consistent with the gauge’s marked radius. If the fiber bends more tightly than the gauge’s groove (i.e., the radius is smaller), it indicates the bending radius is below the standard, and adjustments are needed. Step 4: Repeat the detection at multiple bent points to ensure overall compliance.

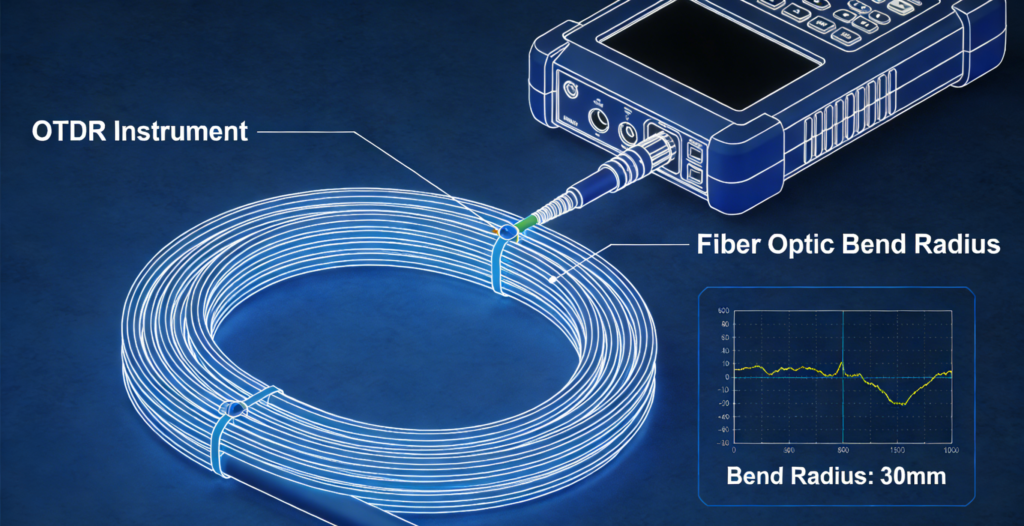

Optical Time-Domain Reflectometer (OTDR)

OTDR is used for indirect detection of bending radius by analyzing signal loss. It is suitable for large-scale fiber networks or hidden fiber sections. Step 1: Connect the OTDR to the fiber under test, ensuring the connection is tight and free of extra loss. Step 2: Set appropriate test parameters (e.g., wavelength, pulse width) based on the fiber length and type. Step 3: Start the test; the OTDR will generate a curve showing signal loss along the fiber. Step 4: Analyze the curve—abnormal sudden loss peaks usually indicate excessive bending. Combine the fiber routing map to locate the bent section, then use a mechanical gauge to measure and adjust the bending radius. Step 5: After adjustment, retest with OTDR to confirm that the loss returns to the normal range.

Note: When using detection instruments, avoid damaging the fiber surface. For mechanical gauges, do not pull or press the fiber hard; for OTDR, ensure the test wavelength matches the fiber to avoid inaccurate results.

Final Thoughts

Fiber bending loss is influenced by bending radius, fiber diameter, material, and structure—but with the right practices, it’s easy to mitigate. By prioritizing proper handling, using suitable fibers, and following installation guidelines, you can maintain high signal quality and extend the life of your fiber optic system.