In an era defined by the rapid advancement of artificial intelligence (AI) technology, the demand for data processing and the growth of communication capacity have escalated to unprecedented levels. This surge is particularly evident in fields such as big data analysis, deep learning, and cloud computing. Here, communication systems are constantly pushing for higher speeds and greater bandwidths to keep up with the data – intensive operations. Traditional single – mode fiber (SMF), unfortunately, faces a bottleneck. Constrained by the nonlinear Shannon limit, its transmission capacity is nearing its upper boundary. This is where Spatial Division Multiplexing (SDM) transmission technology, led by Multi – core Fiber (MCF), steps in. Widely adopted in both long – distance coherent transmission networks and short – distance optical access networks, MCF has significantly enhanced the overall transmission capabilities of networks worldwide.

How MCF Works: A Breakthrough in Fiber Technology

MCF represents a revolutionary leap in fiber optic technology. By integrating multiple independent fiber cores within a single fiber, it overcomes the limitations of traditional single – mode fibers, substantially increasing transmission capacity. A typical MCF contains four to eight single – mode fiber cores, evenly distributed within a protective sheath with a diameter of around 125um. The beauty of this design is that it boosts overall bandwidth without increasing the outer diameter of the fiber. This makes MCF an ideal solution for meeting the explosive growth of communication demands in the AI era.

Diverse Application Scenarios of MCF

Telecommunications Field

MCF has become a staple in various communication setups, including long – distance coherent transmission networks, short – distance optical access networks, and ultra – large – capacity optical communication systems. In data center interconnections, it shines by meeting high – speed and large – capacity communication requirements. This makes it a crucial enabler for data – heavy applications like artificial intelligence, big data analysis, and cloud computing. For instance, in high – speed data transfer between major data centers, MCF uses spatial division multiplexing technology. This allows multiple cores within a single fiber to transmit different signals simultaneously, significantly increasing the overall transmission capacity.

Medical Field

In the medical sector, MCF has found its place in imaging systems. For example, it is used in the loops of fiber optic gyroscopes, enhancing the resolution and accuracy of medical imaging. This improvement in imaging quality aids in more precise diagnoses. Additionally, MCF is valuable in treatment devices that require high – power laser transmission, such as in laser surgery. Here, multiple cores can transmit lasers with different parameters, enabling customized treatment approaches for various medical conditions.

Industrial Field

In industrial automation control systems, MCF serves as a reliable link between distributed sensors and controllers. It enables high – speed and reliable data transmission, ensuring seamless operation of automated processes. Moreover, MCF is used in the internal communication networks of large factories. By connecting production workshops and management departments, it facilitates the quick dissemination of production information, optimizing overall factory operations.

Challenges and Solutions in MCF Application

The widespread use of MCF comes with its own set of challenges, mainly related to fiber connections. Connecting MCFs to each other and to traditional fibers requires careful consideration. To address these issues, the development of peripheral component products such as MCF fiber connectors and fan – in & fan – out devices for MCF – SCF conversion is essential. These components must also be compatible with existing and commercial technologies.

Fan – in & Fan – out Devices for MCF

Connecting MCFs to traditional single – core fibers is made possible by fan – in & fan – out (FIFO) devices. These are key components for achieving efficient coupling between MCFs and standard single – mode fibers. Currently, several technologies are used to create MCF FIFO devices, including the fused biconical taper technology, the Bundle fiber bundle method, 3D waveguide technology, and spatial optics technology. Each of these methods has unique advantages and is suitable for different application scenarios.

MCF Fiber Connectors

While the connection between MCFs and single – core fibers has been addressed to some extent, connecting MCFs to other MCFs remains a challenge. Currently, fusion splicing is the common method for connecting MCFs, but it has limitations. It is difficult to implement and even more challenging to maintain. Adding to the complexity is the lack of a unified standard in MCF production. Different manufacturers produce MCFs with varying core arrangements, sizes, and spacings, making fusion splicing more difficult.

MCF fiber connectors are designed to solve these connection problems. They are used to connect MCFs to each other and to other types of fibers or devices. Common interface types include LC – type, FC – type, and MC – type. LC – type and FC – type MCF fiber connectors are redesigned versions of traditional LC/FC connectors. They feature optimized positioning and retention functions and an improved grinding and coupling process, ensuring minimal change in insertion loss even after multiple couplings. The MC – type connectors, with their dedicated design, are smaller in size and ideal for space – constrained scenarios.

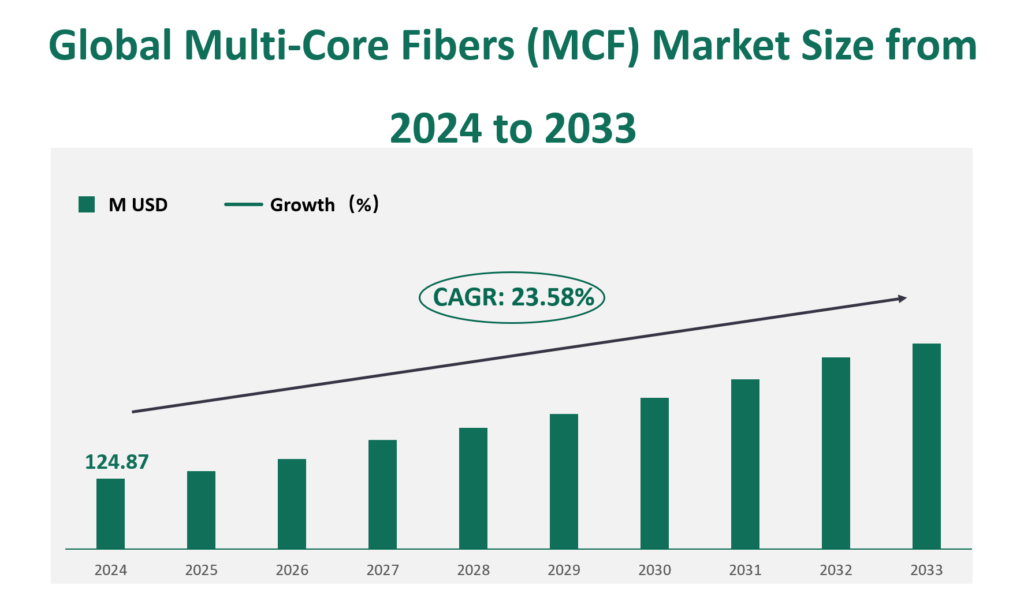

The Booming MCF Market

The future of MCF looks extremely promising, and market statistics back this up. According to the 2023 “MULTI – CORE FIBERS (MCF) MARKET REPORT” by Businessresearchinsights, the global MCF market size was $1.836 billion in 2022. It is projected to reach a staggering $21.63265 billion by 2031, with a compound annual growth rate of 32.3% during the forecast period.

The market is highly competitive, with major players such as Furukawa Electric (Japan), Yangtze Optical Fibre and Cable (China), Fiberhome (China), iXblue (France), Humanetics (United States), Fujikura (Japan), and Sumitomo Electric (Japan). The top three companies alone hold more than 70% of the market share, indicating a concentration of innovation and expertise.

Geographically, the Asia – Pacific region dominates the market, accounting for more than 65% of the share. North America and Europe follow, with approximately 20% and 10% shares, respectively. In terms of product types, four – core fibers are the largest market segment, making up around 60% of the share. And in product applications, the communication field leads with a market share of over 55%.

In conclusion, as we continue to ride the wave of the AI revolution, Multi – core Fiber is set to be a crucial element in our pursuit of faster and more efficient communication. With continuous technological advancements and a rapidly expanding market, the potential of MCF is boundless, and the future of connectivity has never been more exciting.