The Power of Fused Optic Fiber Bundles

In the rapidly advancing realm of photonics, optic fiber technology stands as a cornerstone, constantly redefining the boundaries of technological possibilities. From enabling lightning – fast internet connections to driving innovative medical treatments, optical fibers have become an integral part of modern life. But a pressing question emerges: How can we efficiently transmit light through multiple channels simultaneously, with pinpoint precision and minimal energy loss?

Our Proprietary Heat Fusion Technology

Our company has independently developed a state – of – the – art heat fusion technology, backed by relevant patents. This technology employs self – engineered equipment and processes to achieve seamless, glue – free bonding between optical fiber bundles. Once the heat fusion process is complete, the claddings of each individual optical fiber are tightly fused together, eradicating any gaps between them. This not only eliminates the negative impact of adhesives on the optical fiber bundle but also significantly elevates the bundle’s tolerance to high laser power. Additionally, the process streamlines the manufacturing workflow, saving production time and maintenance costs.

Precision – Engineered Fused Fiber Arrays

Traditional fiber bundles typically rely on adhesives or mechanical clamps to hold the fibers in place. Although these methods are serviceable in some applications, they come with inherent limitations in terms of thermal stability, mechanical resilience, and optical performance. Here, our heat fusion technology takes center stage.

Through the careful application of precisely controlled heat, individual fibers within a fiber array are fused into a single, monolithic structure. This results in a connection that is seamless, robust, and incredibly precise. The advantages are manifold:

- Superior Mechanical Strength: Fused fiber bundles are far more durable and can withstand substantial physical stress compared to their adhesively – bonded counterparts. This makes them ideal for applications in harsh environments.

- Enhanced Thermal Stability: Heat fusion eliminates the issue of thermal expansion mismatch that often plagues adhesively – joined bundles. As a result, the fused fiber arrays maintain consistent performance across a broad temperature spectrum.

- Minimal Optical Loss: The seamless fusion reduces scattering and reflection losses to a minimum, optimizing light transmission efficiency. This is crucial for applications where every photon counts, such as in high – power laser systems.

- Ultra – Precise Fiber Alignment: Heat fusion allows for the exact positioning of fibers, which is essential for applications that demand precise spatial control of light, like in advanced imaging systems.

Applications Spanning Diverse Industries

The unique characteristics of fused optic fiber bundles open up a world of possibilities across a wide range of industries:

- Laser Therapy: In the medical field, fused fiber bundles play a pivotal role in delivering laser energy precisely to targeted tissues. This is particularly critical in minimally invasive procedures, where precision and minimal tissue damage are of utmost importance. For example, in dermatology, they can be used to treat skin conditions with high – precision laser pulses, or in ophthalmology for delicate retinal surgeries.

- Spectrum Analysis: Fused fiber arrays are indispensable in spectroscopy. They enable the simultaneous measurement of light intensity across a wide range of wavelengths. This is invaluable for applications such as chemical analysis, where the ability to identify and quantify chemical compounds accurately is essential. In material characterization, it helps in understanding the optical properties of different materials, and in astronomical observation, it allows for the analysis of light from celestial bodies to determine their composition and physical properties.

- Environmental Monitoring: Optic fiber sensors, often integrated within fused bundles, are deployed to monitor various environmental parameters. These can include temperature, pressure, and chemical composition. In remote areas or challenging environments, such as deep – sea or high – altitude regions, these sensors can collect real – time data, providing crucial insights for environmental research, climate change studies, and pollution monitoring.

- Industrial Inspection: Fused fiber bundles find extensive use in endoscopes and other imaging systems for industrial inspection. They enable detailed visualization of internal structures and defects in machinery, pipelines, and electronic components. This helps in early detection of faults, reducing downtime and maintenance costs in industrial operations.

- Telecommunications: While single – mode fibers form the backbone of long – distance telecommunications, fiber bundles are essential in complex switching and routing systems within data centers and communication networks. They facilitate the efficient distribution of data signals, ensuring high – speed and reliable communication within these infrastructure hubs.

Customization for Your Needs

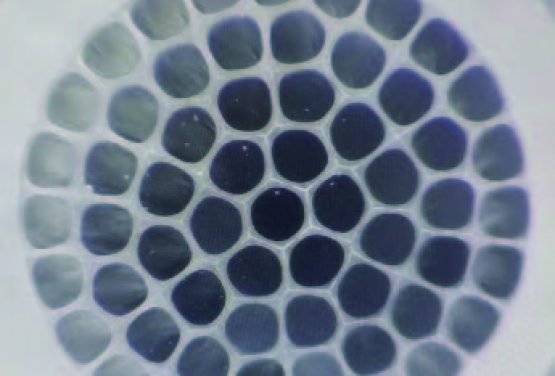

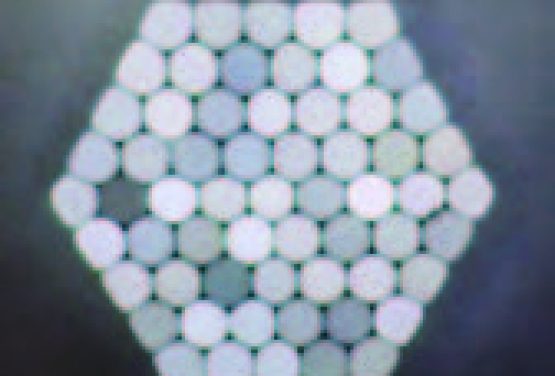

We offer comprehensive customization services for heat – fused optical fiber bundles. Whether you need specific types of optical fibers, connectors, cross – sectional shapes, or lengths, we can tailor the bundles to meet your exact requirements. For instance, we can provide 61 – core circular arrangements, 61 – core hexagonal arrangements, or 16 – core rectangular arrangements, as shown in the product end – face pictures .

If you require our expertise or have any inquiries regarding our fused optic fiber bundles, please do not hesitate to contact us. We are committed to providing innovative solutions for all your photonics needs.